Non-unidirectional Flow Clean Room Contamination Control Technology for the Pharmaceutical Industry

News & Insights2023-09-15

How can HVAC systems be properly used in pharmaceutical factories?

There are various factors that affect the quality of drugs in the drug production process, including pollution caused by ambient air, drug cross-contamination and confusion, and human errors. As an important component of the drug production quality control system, the pharmaceutical HVAC system mainly controls and monitors the air temperature, humidity, suspended particles, and microorganisms in the drug production environment to ensure that the environmental parameters meet the requirements of drug quality, avoid the occurrence of air pollution and cross-pollution, and provide a comfortable environment for operators. HVAC systems play a key role in pharmaceutical factories' ability to achieve their goal of providing safe and effective products to patients.

In traditional engineering construction, concerning the HVAC system, the designer is often only focused on the hardware of the air conditioning system itself, such as whether there is surplus air volume and whether the filter configuration meets the requirements while ignoring whether the air sent into the clean room by the air conditioning system really brings pollutants out of the clean room. Although GMP, ISO14644, and other standards provide limits on the concentration of suspended particles at each clean level, it is difficult to accurately evaluate the removal efficacy of pollutants in clean rooms by using conventional design methods. Designers often increase the number of air changes to improve the reliability of clean room operation, which results in high energy consumption of pharmaceutical clean rooms. Therefore, reasonable airflow organization can not only ensure the parameters of a clean environment but also improve the removal efficacy of pollutants in the clean room and reduce the overall energy consumption of the clean room.

How to control the airflow to ensure the cleanliness level?

1)Proper airflow organization

People usually prefer to feel mild air flow, so the air velocity design in the office environment is generally 0.1m /s. However, in order to ensure the cleanliness of the production environment, a large wind speed air velocity (1m/s) is usually required to remove particles from the air. In the production environment, the operator may require greater air velocity when they feel uncomfortable in heavy clothing.

Making the air in a space flow in a pre-required direction is called airflow organization. Proper airflow organization helps to quickly meet the temperature and classification requirements of the environment, helps prevent harmful environmental pollutants from adversely affecting products and mutual contamination of products, and reduces mutual contamination between operators and products.

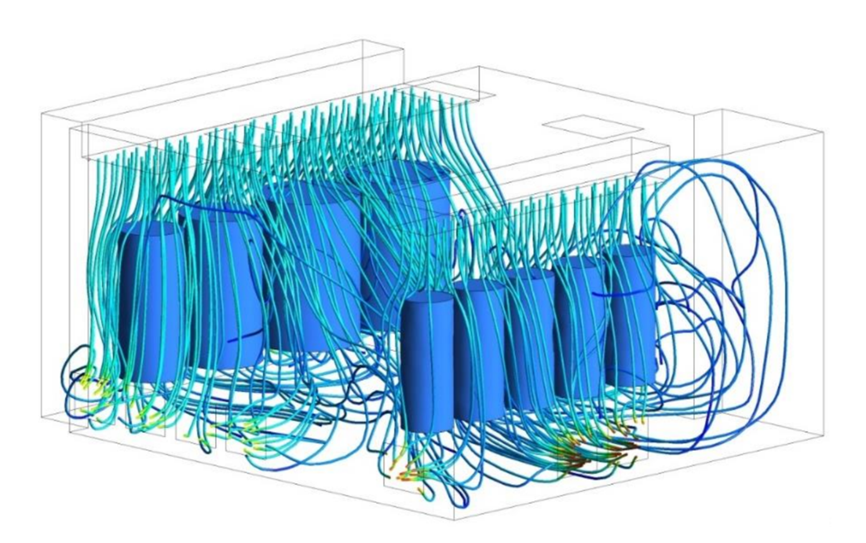

2)Simulation technology

Computational Fluid Dynamics (CFD) is a simulation technology. The basic principle is to numerically solve the differential equations governing fluid flow, to obtain the discrete distribution of the flow field in a continuous region, so as to approximate the real fluid flow situation. Its application in HVAC engineering is mainly to simulate and predict the flow of air or other fluids indoors and outdoors or within equipment. Engineers use computational fluid tools such as ANSYS to build models, input assumptions, perform software analysis, and output results. Meanwhile, a detailed distribution of physical parameters in the process such as speed, temperature, humidity and concentrations of harmful substances in the room can be foreseen.

Simulation of airflow organization in a Car-T workshop project

In order to obtain a good airflow organization and thus better control the clean room environment, the following factors are mainly considered in the air flow organization simulation of this project:

1)Reasonable number of air changes. The influence of the number of air changes is much greater than other factors, but the number of air changes recommended by the current specification is usually large, resulting in an increase in the air volume supply, air conditioning load and investment.

2)Reasonable inlet and outlet position. The location of the inlet and outlet is the main affecting factor of the ventilation efficacy, rather than just the number of air changes. For the indoor area, to arrange the HEPA in the center of the ceiling can effectively improve the removal efficiency of indoor pollutants. It is generally recommended that the arrangement of the room air outlet should be as uniform as possible, to avoid the dead spots of the supply and return air in the room. At the same time, the return air should be symmetrical as far as possible with best effect when air returns are in opposite sides.

3)Reasonable process layout. The production equipment often blocks air flow. The height of production equipment, width of the working area, and the relative position between the working area and the outlet will affect the cleanliness of the clean area. In addition, it’s worth to pay attention about the shielding effect of tall equipment on the air supply outlet.

4)Other factors. The room geometric dimensions, open mesh flooring spacing, the production equipment height, the working area width, and the relative position between the working area and the outlet.

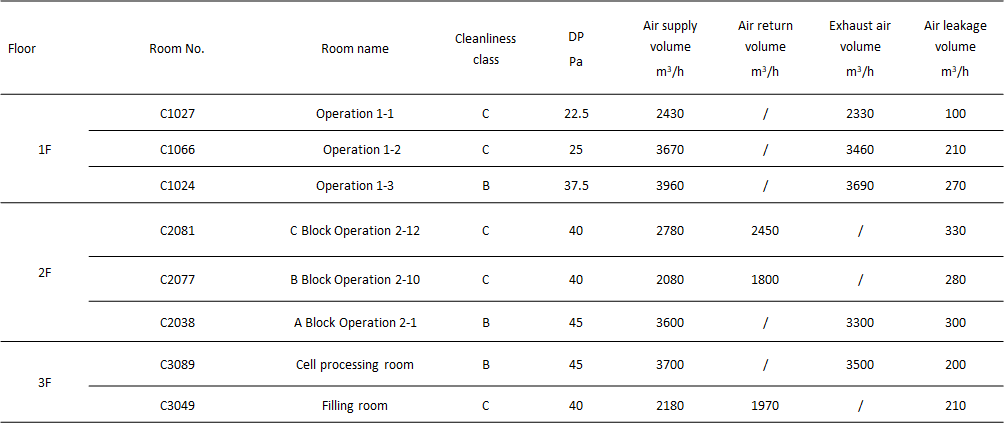

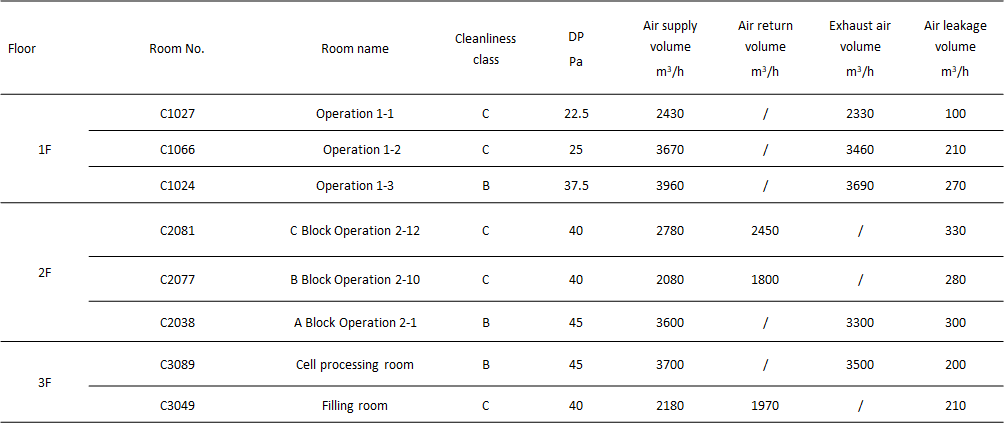

Simulated Room

Sheet 1 Simulated Room Basic Information List

Simulation results

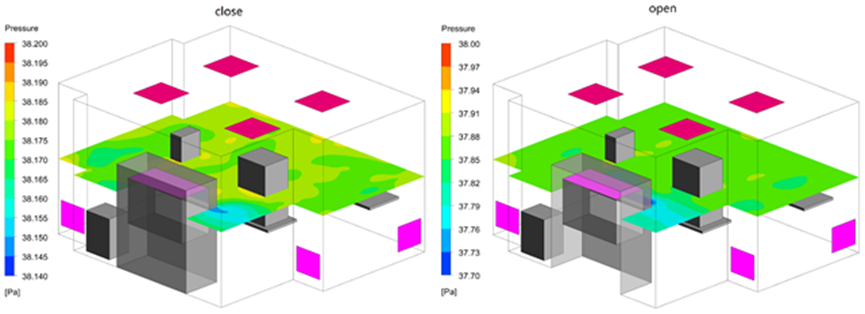

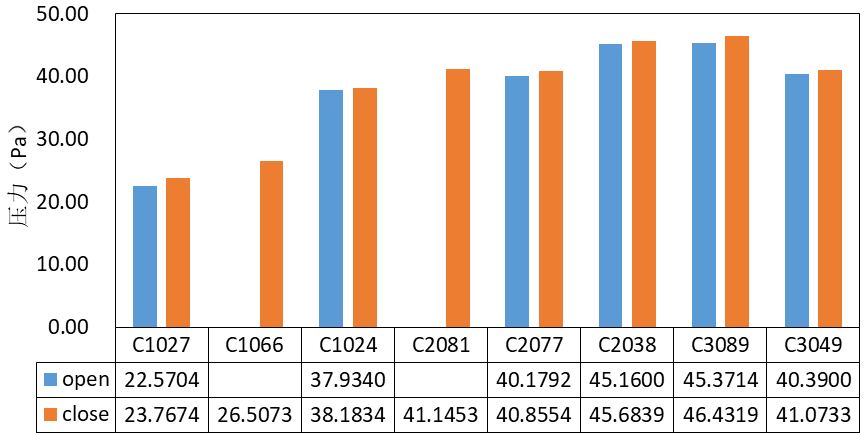

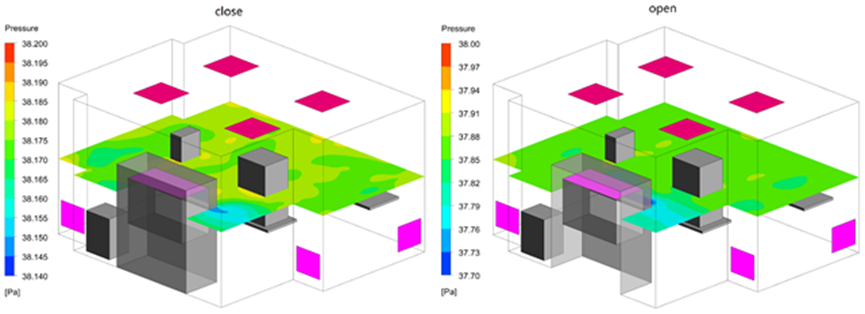

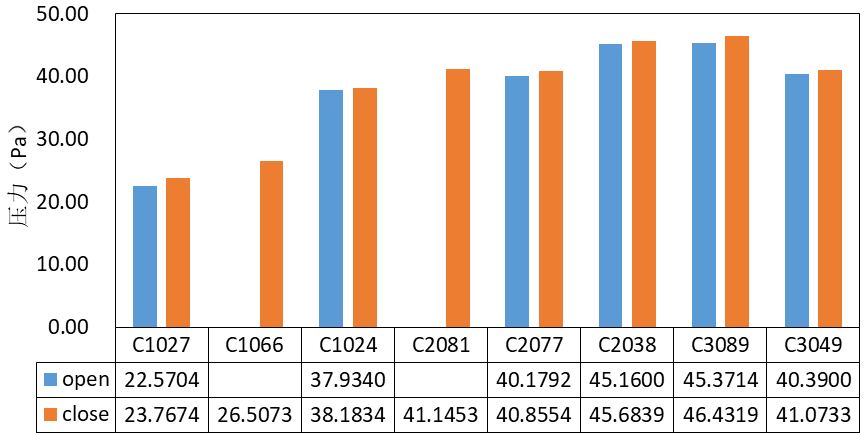

▶Average room pressure:38.1834Pa(close);37.9340Pa(open)

▶Average pressure on Z=1.5m section:38.1791(close);37.9176Pa(open)

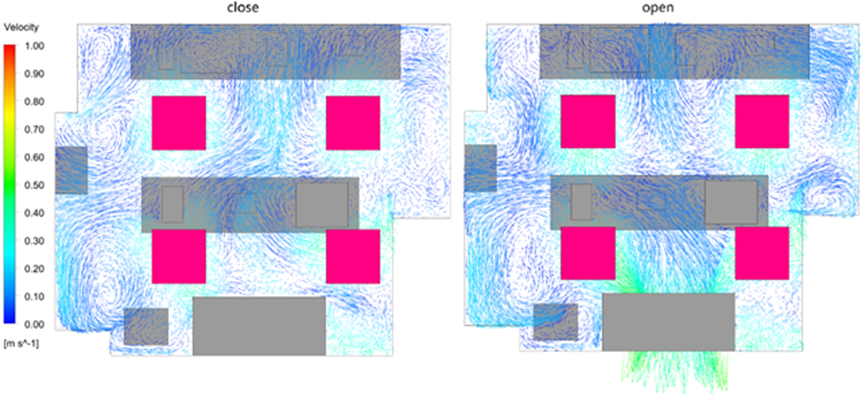

▶Average velocity on Z=1.5m section:0.165m/s(close);0.192m/s(open)

(a)Pressure nephogram

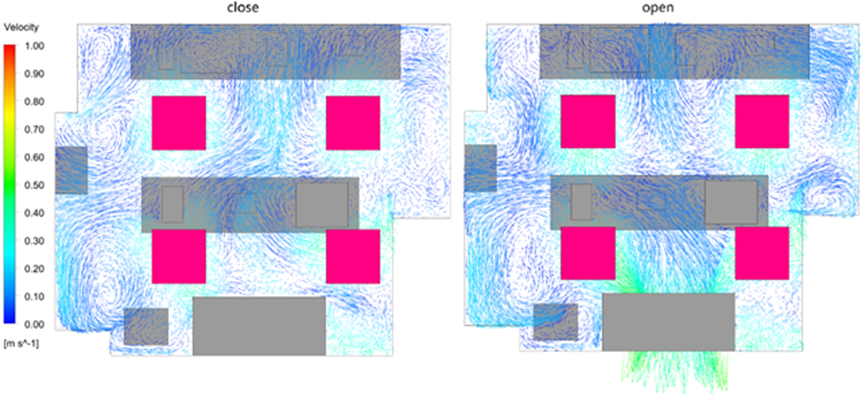

(b)Velocity vector diagram

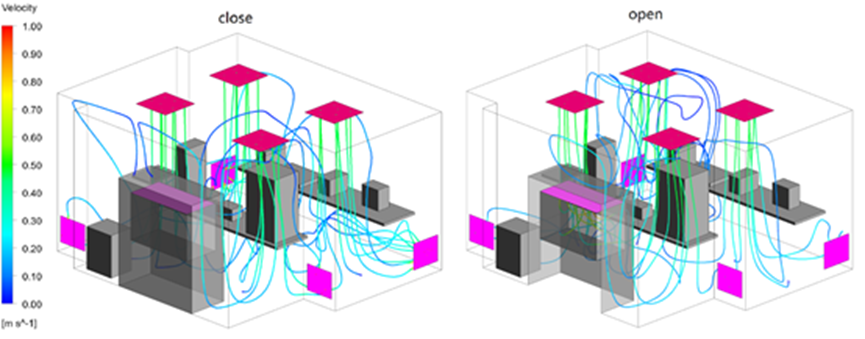

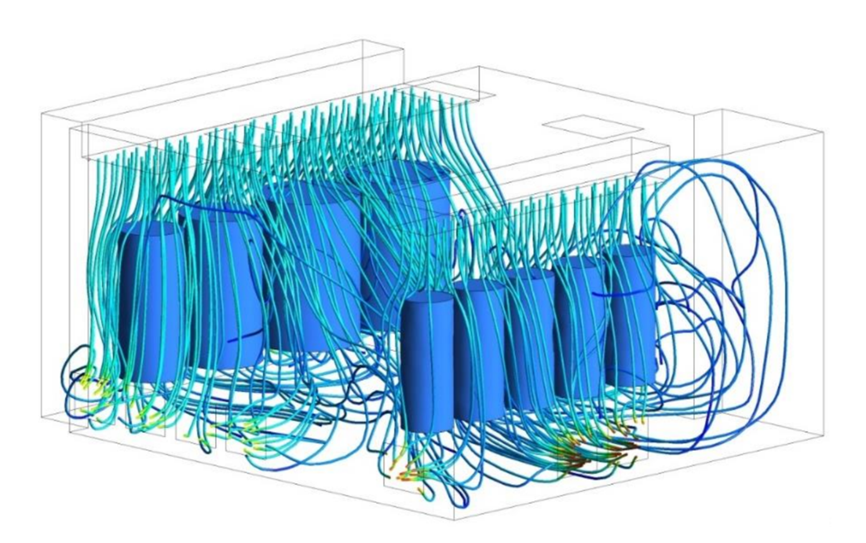

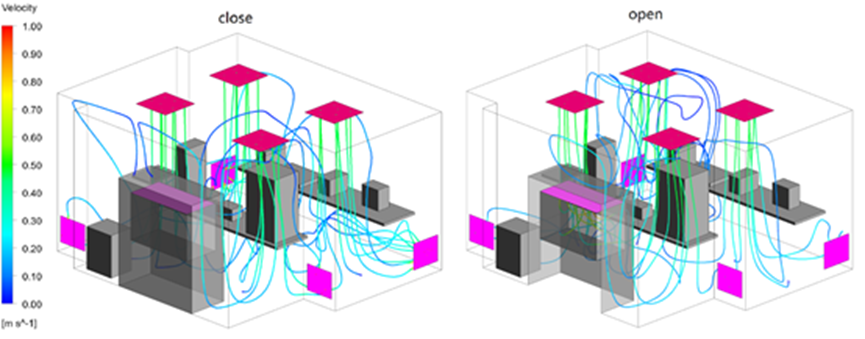

(c)Air flow diagram

(c)Air flow diagram

How does airflow organization simulation benefit the project?

1)The visualized airflow organization of each room in the core production area intuitively reflects the flow field of the core production area.

2)Optimize the design drawing, and solve the unreasonable design of the inlet and outlet setting which is easy to cause air short circuits, eddy currents and others that are not conducive to air replacement, so as to improve the uniformity of airflow organization in the clean room and help eliminate pollutants.

3)Simulate the influence of clean room pressure when the biosafety cabinets, isolators and other equipment are opened. The simulation results can guide the formulation of a VAV control strategy for air conditioning BMS system so that the fluctuation range of room pressure can be within ±1Pa when the process equipment is opened.

CFD technology is used to accurately calculate the details of fluid flow, so as to find the problems in the design and simulate the airflow organization in the clean area. The distribution of airflow velocity field/temperature field/concentration field in the clean area should be considered from the design stage of the building scheme to reduce problems such as airflow short circuits, eddy currents, and dead spots in the clean area. Make the production area ventilated effectively, meet the specified requirements to the greatest extent, and terminate with the prejudice that it is difficult to quantify the airflow pattern during design.

Search

Search 中文

中文