Tangential Flow Filtration and Depth Filtration in Plasmid DNA Manufacturing

News & Insights2023-12-21

As plasmid DNA makes inroads into the world of biopharmaceuticals, the need to manufacture it will spiral. The growing demand for plasmid DNA for gene therapy and third-generation vaccines has encouraged the development of simple, robust and scalable production bioprocesses.

AUSTAR Group depth filtration (DF) system and tangential flow filtration (TFF) systems are designed for plasmid DNA’s production and purification, including the clarification, concentration, and buffer replacement post of lysate, and desalination after ion exchange.

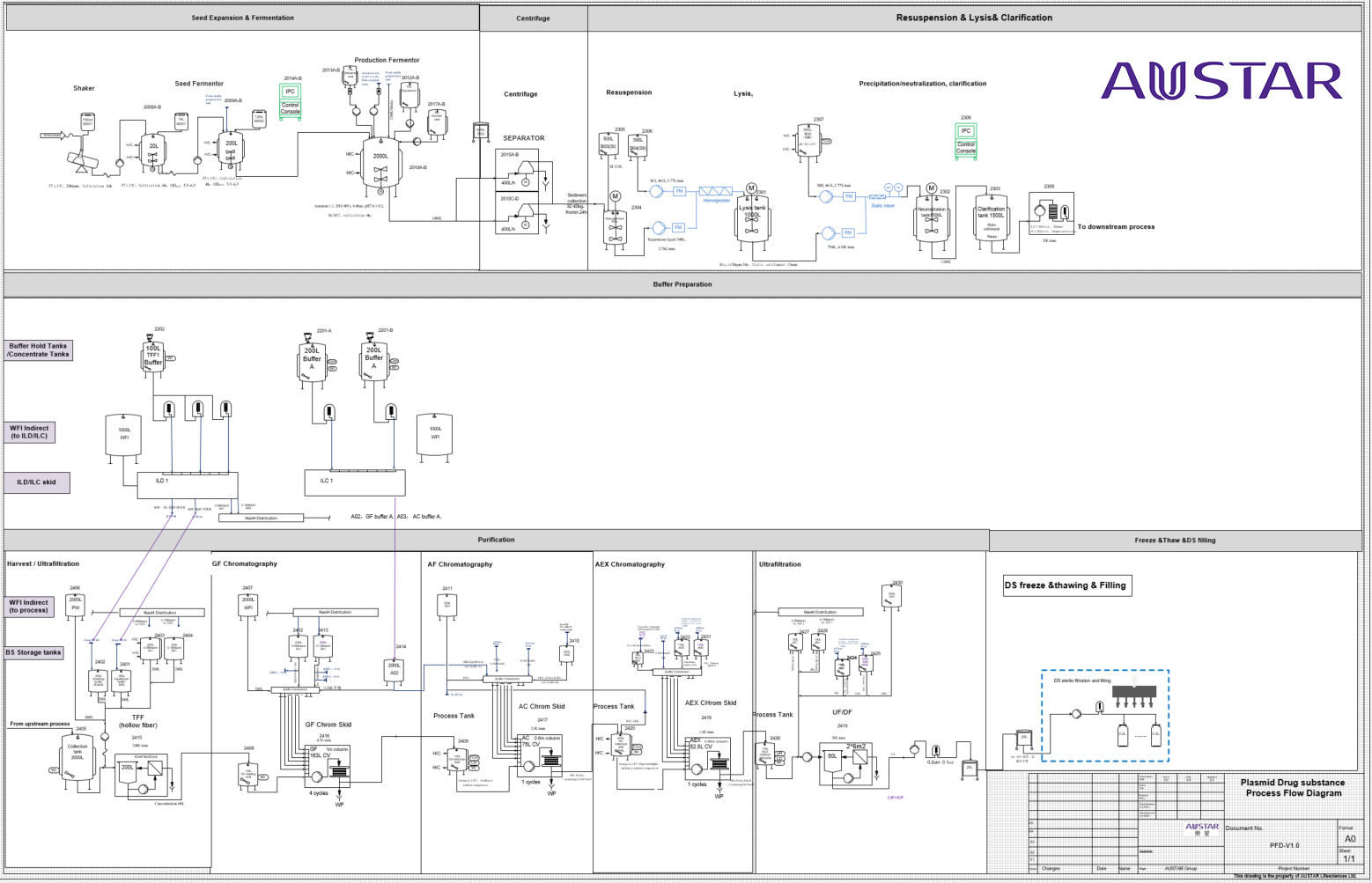

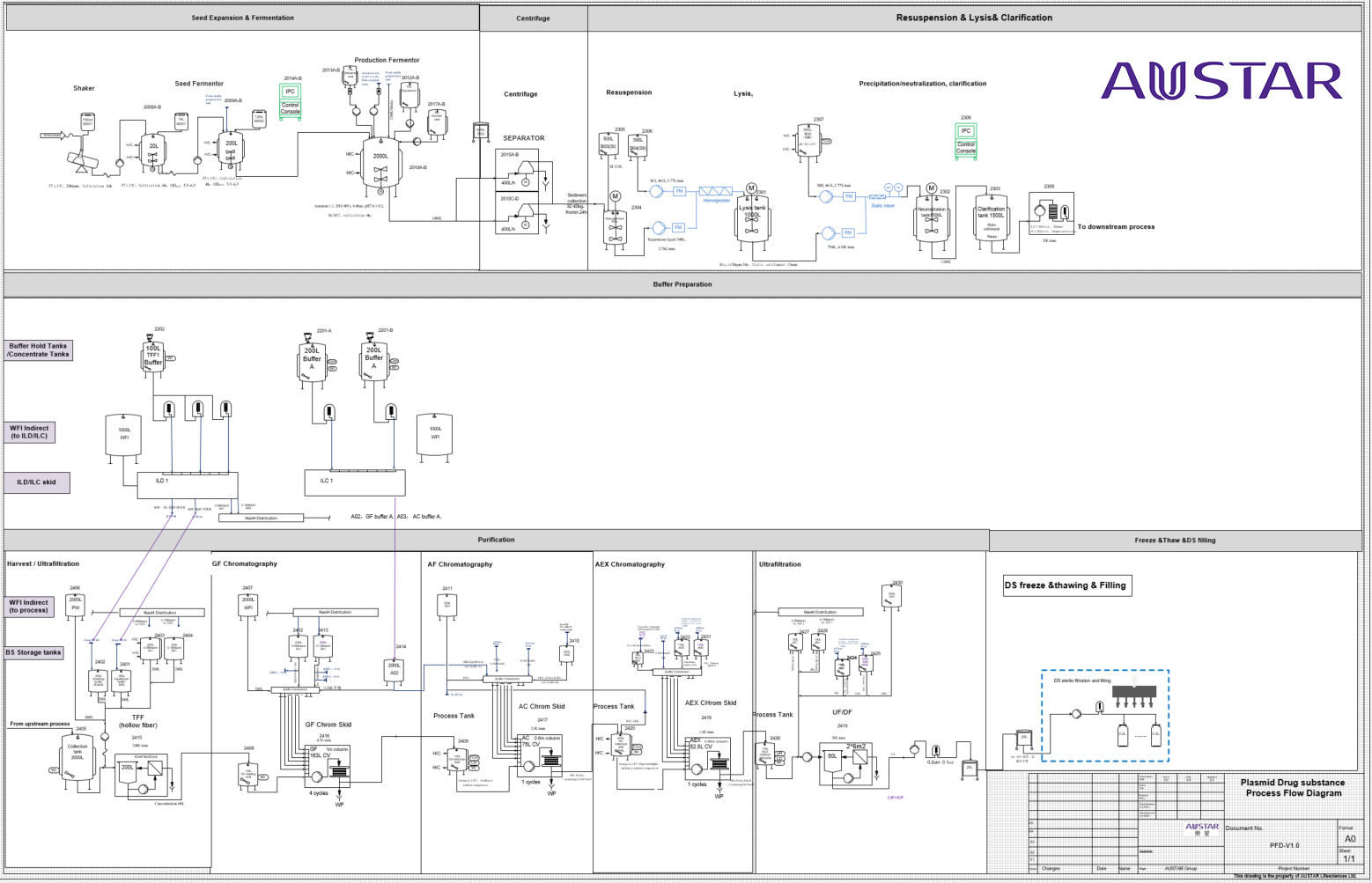

Plasmid DNA Manufacturing Process Flow

The picture shows the whole process steps of a typical plasmid DNA platform technology. During the three stages of E. coli fermentation, when E. coli grow to a certain OD value, the harvesting step is performed by centrifuge at 5000G. After harvesting the E. coli, further process is carried out by washing, suspension of bacteria with normal saline, and then cell lysis, neutralization & renaturation with a specific buffer. The last step of the upstream process is depth filtration to remove the cell fractions. Then the clarified intermediate product is transferred the downstream of process.

At the downstream of the process, 3 steps of Purification are used to remove RNA, ocDNA & linear DNA. At the last step of anionic chromatography, the removal of endotoxin and HCP is accomplished. Then the DS (drug substance) process is performed by concentration, buffer replacement and final finish of formulation.

How Are Tangential Flow Filtration and Depth Filtration Used In pDNA Production?

During TTF/DF, the plasmid is dia-filtrated and concentrated in the appropriate buffer. Both hollow fiber membrane concentration and flat membrane concentration are typically performed by using tangential flow filtration (TFF) as this technique which is easily scalable, highly selective, and cost-effective.

AUSTAR Hollow Fiber Membrane Tangential Flow System

The hollow fiber membrane TFF prior to chromatography is used to perform the concentration step & subsequent diafiltration step to further improve downstream of purification.

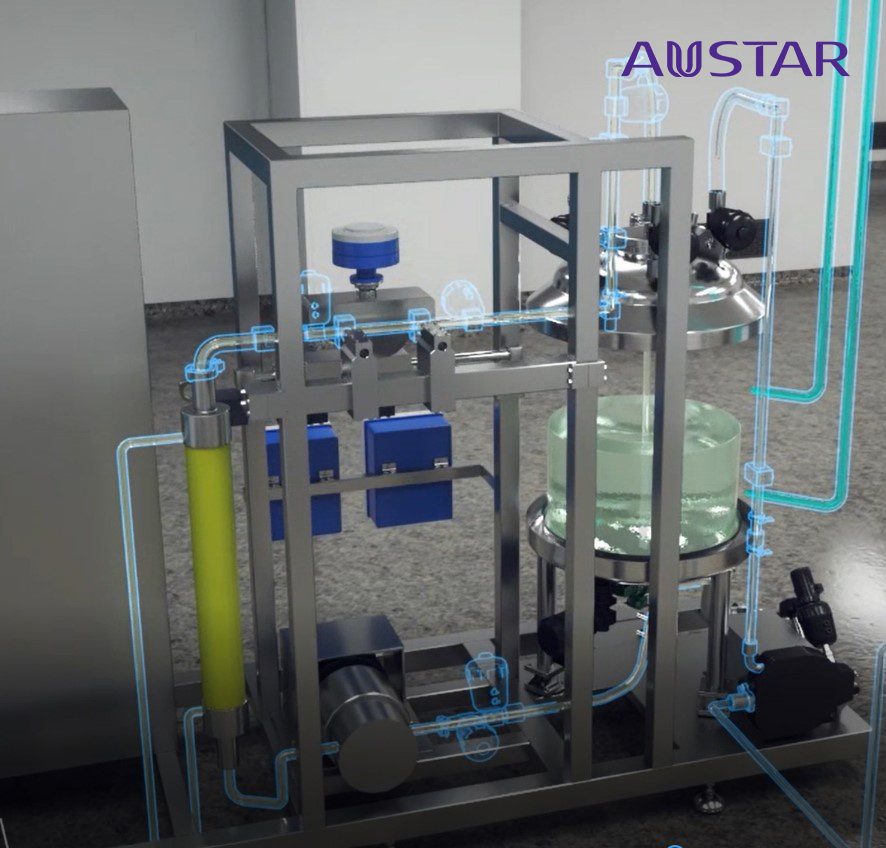

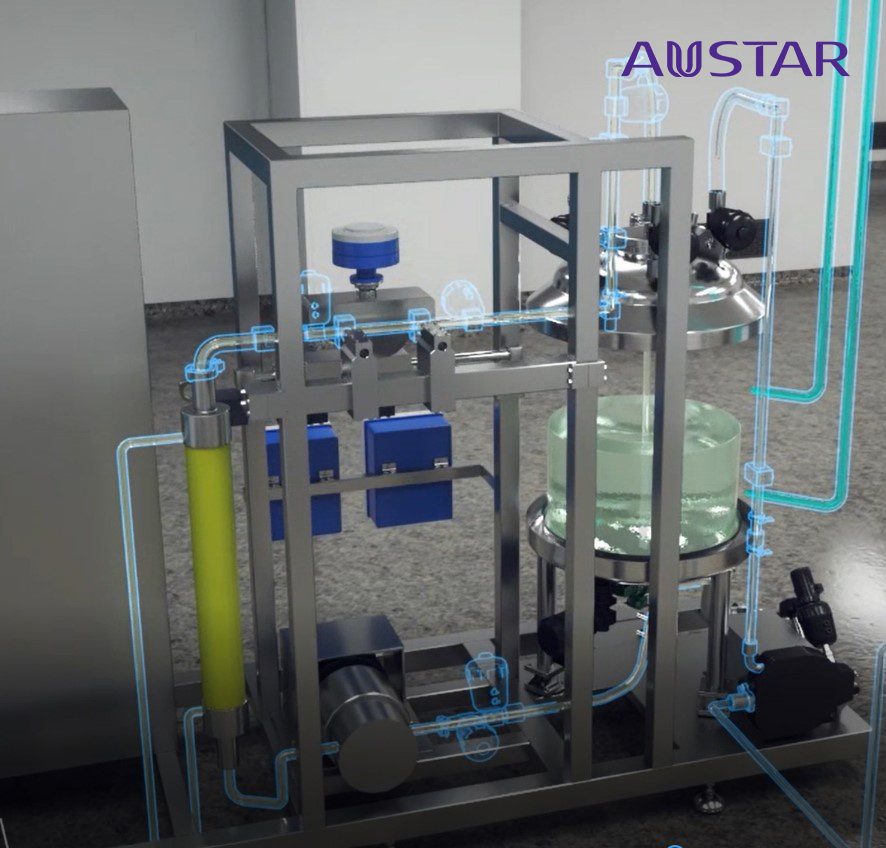

AUSTAR Hollow fiber membrane tangential flow filtration system is mainly composed of a membrane column, tank, diaphragm pump, pipeline, valve, sensor and control system. Automatic cleaning of the membrane holder can be realized. The system can automatically feed buffer, PW and lye, and automatically adjust TMP to achieve diafiltration and ultrafiltration.

AUSTAR Flat Membrane Ultrafiltration System

After ion exchange chromatography, plasmid DNA is to be concentrated by ultrafiltration. During ultrafiltration, the smaller molecules such as buffer, and salts are penetrated through the membrane and the plasmid DNA is retained & concentrated. The performance of TFF depends on the feed flow, TMP and MWCO (molecular weight cut-off), and the pore size of the membrane.

AUSTAR flat membrane ultrafiltration system is mainly composed of a fixture, tank, diaphragm pump, pipeline, valve, sensor and control system. The system can automatically feed buffer, PW, and lye, clean the film package, and automatically adjust TMP and water flux tests according to customer requirements.

AUSTAR Depth Filtration System

Depth filtration is usually followed by hollow fiber membrane TFF. For the liquid after cell cleavage and renaturation, cell fragments need to be removed to obtain a clarified pDNA-rich liquid. In in-depth filtration, the cell fragments are separated by the depth filtration membrane.

AUSTAR depth filtration is mainly composed of a rotor pump, pipeline, valve, sensor and control system, etc., it can realize automatic WFI flushing of the depth filter membrane package, and the system can automatically feed buffer, WFI and lye, and automatically adjust the membrane pressure.

At AUSTAR, we offer clients customized design services and a one-stop membrane system overall solution for Plasmid DNA manufacturing. Our depth filtration systems, flat membrane ultrafiltration systems, and hollow fiber membrane tangential flow filtration systems can be compatible with many other depth filtration membranes, ultrafiltration membranes, and hollow fiber membrane products.

Search

Search 中文

中文