Strategy Research Based on Autodesk Revit API Development Plug-in in Cleanroom Color Steel Plate Ceiling Design

News & Insights2024-06-07

As cleanrooms are widely used in the pharmaceutical, electronics, and bioengineering industries, the design and construction of cleanroom interior decorative materials are of great importance. This article is intended to study through the Autodesk Revit API interface, through the "Visual Studio" using the class in the C# language to define the object's attributes and behavior, using the application of WPF forms to develop the main program plug-ins, to improve the cleanroom color plate ceiling design efficiency strategy.

In this article, we first analyze the current problems and challenges in the design of cleanroom color steel ceiling, and then discuss the advantages and feasibility of developing custom plug-ins through Revit API. Finally, we propose specific strategies and approaches to improve the efficiency of design and drawing, reduce design costs, and enhance the quality and sustainability of cleanroom interiors.

Analysis of Problems and Challenges

Lots of repeated activities exist in the current cleanroom color steel ceiling design, such as setting up the color plate, making detailed drawings, etc. Designers need to spend a lot of time and energy, increasing the drawing time, decreasing the accuracy, and too much manpower operation. Visualization and collaborative design is insufficient. The traditional design makes it difficult to realize real visualization and collaborative design. There are barriers to the transmission of information between design and construction, which can easily lead to a mismatch between the design and the actual construction.

Advantages and Feasibility Analysis of Revit API Plug-in Development

Autodesk Revit, as a professional BIM software, has abundant API interfaces to support developers in customized development based on actual needs, thus effectively solving the limitations of traditional design software.

Using Revit API can realize automated design process and parametric modeling of color steel ceiling by programming, significantly improving design efficiency and reducing repetitive activities.

Plug-ins developed based on Revit API can enable the visual design, and designers and construction parties can perform collaborative design on the same platform to improve the match between design and construction.

Strategies and Approaches

Background Description:

Cleanroom, as a special room environment, its ceiling panel design is crucial for realizing a clean environment. However, the traditional process of designing ceiling panels for cleanrooms can be improved regarding design accuracy, drawing efficiency, material placement accuracy, and complicated manual operations.

Application Objective:

Given the above problems, it is expected to realize the color plate in-depth drawing and accurate, efficient, and automated material placement, achieving improvement in production efficiency and product quality, reducing production costs, manual calculation errors and manual drawing errors, and increase the drawing efficiency, one-click drawings and bill of materials.

Solution:

Using Revit API to develop automation tools to realize the rapid arrangement of color plate ceiling, one-click drawing and automatic generation of bill of quantities to reduce repetitive activities and improve design efficiency. Visualize the ceiling design effect through the 3D graphical interface, improve the communication efficiency between designers and customers, and reduce the number of design modifications.

First of all, based on the plug-ins made by Visual Studio using RVEIT API, the enclosure design engineers are provided with the functions of "ceiling layout, ceiling detail drawing and ceiling list", which optimize the engineers' work content and enhance the work efficiency, save man-hours and reduce the labor cost.

Color plate ceiling layout:

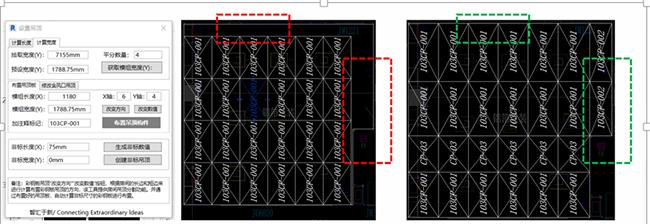

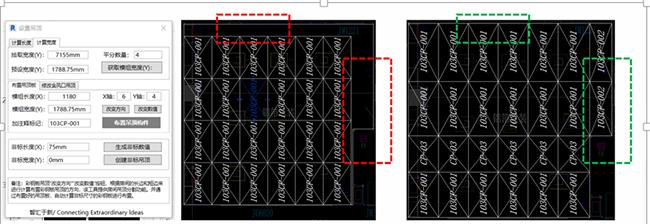

pick-up ceiling room border - plug-in automatically obtained values through the plug-in calculation width (length) "1180 ×", based on pick-up room border, color plate length/width is calculated, and the number of equal shares is calculated. Input the color plate code to complete the room color plate ceiling layout, using the main program family instance parameters for secondary modification of non-standard areas, or global division for the grid approach, then the integrated ceiling layout.

Notice:

The secondary adjustment to comply with the operating habits of engineers, emulate CAD software to enhance the parameters added to the attributes, the arrangement of the color plate ceiling, set by instance parameters. It is possible to enter the value, drag and drop to adjust the parameters.

Factors for secondary adjustment:

Secondary electromechanical optimization, integrated ceiling layout drawings, etc. Regarding the color steel plate related points, "HEPA air supply vent", during the secondary adjustment, the air vent display and size adjustment is controlled by Revit parameters.

Functions Realized:

Calculate the width/length of the room, set the number of layouts, and automatically lay out the set color plate family. Add a "color plate code" for production processing by entering a comment mark.

Add Gadgets:

The direction of the X/Y axis of the array is changed and the width and length values are set according to the width and length of the room. The number of ceilings arranged in the room is set up successfully, which can generate the value of non-standard dimensions that are not evenly arranged, and the non-standard dimensions ≥ 200mm can be reviewed, and whether the non-standard dimensions can be processed or not can be calculated in advance.

The program realizes one-click creation of ceiling panel detail drawings for users, automatically counts the number of color plate detail drawings with the same code, and can automatically generate hole annotations and other related information, thus greatly simplifying the complex tasks in the process of engineering design and improving the work efficiency and accuracy. In addition, the plug-in also supports further functionality, such as optimizing the layout of drawings, custom marking style, intelligent identification of specific elements in the drawings, etc., to provide users with more comprehensive and personalized design and marking solutions.

One-click export BOM: Help users rapidly count the parameters required for processing of color plate ceiling, and export them into a standard format BOM for submission to the factory for processing. This feature may include the following:

-Color steel plate specifications: code, size, quantity, area, and other parameters.

-Users can fill in the relevant information or select the preset options, and the system automatically generates a BOM that meets the factory processing needs, thus improving efficiency and ensuring accuracy. In such a way, users do not need to manually organize the BOM manually, thus quickly and accurately completing the process of submitting orders to factories to process color plate ceilings.

Conclusion

This article proposes a plug-in development strategy based on Autodesk Revit API for addressing the problem of inefficient design of color plate ceilings in cleanrooms. By taking advantage of the abundant interfaces and functions of Revit API, developing automation tools, realizing visual design, and strengthening collaborative design functions, we can effectively improve the design efficiency, meet the customization requirements, and promote the quality and continuous improvement of the interior design of cleanrooms. In the future, we will further deepen the functions and performance of the plug-ins to promote the digital transformation and intelligent development of the cleanroom design industry.

Search

Search 中文

中文