Effect of the Design of the Ice Condenser on the Product Quality during Freeze-Drying

News & Insights 2024-07-22

Introduction

The condenser is the most critical component of a freeze dryer. In freeze-drying, it is the condenser that removes the water vapor from the drying chamber. Therefore, the condenser is also known as the "water vapor pump".1 The design and performance of the condenser have a direct effect on the water vapor transfer during freeze-drying, and could impact critical parameters such as product temperature and chamber pressure, and furthermore, could affect the product quality attributes.

This article will give an overview of the important factors of the design of a condenser and the effect of the design of the condenser on the freeze-drying process.

Resistance to Water Vapor Flow during Freeze-Drying

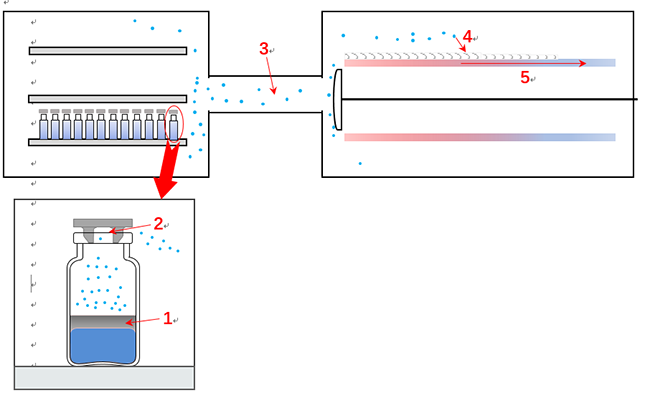

As shown in Figure 1, the transport of water vapor from the sublimation interface to the condenser could encounter the following resistances:2,3

(1)Resistance of the dried-product layer

(2)Resistance of the stopper

(3)Resistance of the duct connecting the drying chamber and the condenser

(4)Resistance to the transport of water vapor in the condenser and conversion to ice

(5)Resistance of the refrigeration system to removal of heat from desublimation of the water vapor

Among the resistances mentioned above, resistance of the dried-product layer is generally the largest and could be 80% to 90% of the total amount of the resistance to the water vapor flow,2 thereby defining the primary drying time and the product temperature during primary drying. Thus, studies normally focus on the resistance of the dried-product layer. In the meantime, the ability of condenser for capturing the water vapor (i.e. resistance (3), (4) and (5)) could also significantly affect the freeze-drying process and the final product quality. If the water vapor could not be removed from the drying chamber or the condenser is overloaded, the chamber pressure could rise rapidly.

The Consequences of Loss of Control of the Chamber Pressure

If the chamber pressure deviates from the setting point and increases rapidly, it could result in the following consequences:

(1)The process could be considered as failed since the chamber is regarded as one of the critical process parameters.

(2)The increase of chamber pressure could lead to increase in heat transfer from shelf to vial and decrease of the "cooling effect" of the sublimation. Both effects could cause a noticeable increase in product temperature and possible shrinkage and even collapse of the final product.

(3)If the loss of the control of the chamber pressure is resulted from the overload of the condenser, large amount of the water vapor could enter the vacuum pump and cause damage to the pump in long-term.

Figure 1:Resistance to Water Vapor Flow during Freeze-Drying: (1) resistance of the dried-product layer, (2) resistance of the stopper, (3) resistance of the duct connecting the drying chamber and the condenser, (4) resistance to transport of water vapor in the condenser and conversion to ice, (5) resistance of the refrigeration system to removal of heat from desublimation of the water vapor.

Requirements for Design of an Ideal Condenser

In order to ensure an efficient removal of the water vapor, the design of the condenser should meet the following requirements:4

(1)The geometry of the duct connecting the drying chamber and condenser should be able to allow transport of large amount of water vapor. The diameter of the duct should be calculated carefully and ensure the velocity of the water vapor flow in duct is lower than 100 m/s. An ideal ratio between the length and the diameter of the duct is about 1.6.

(2)The surface area of the coils could be large enough to ensure that the ice layer on the coils is thin. With increasing thickness of the ice layer, the surface of the ice layer becomes warmer than the coils, thereby slowing down the conversion of water vapor into ice.

(3)The temperature difference between the inlet and the outlet of the coils should be small to ensure a uniform ice condensation on the entire surface of the coils.

(4)Vacuum pump should be connected with the freeze dryer at the lowest position in the condenser. The permanent gases such as oxygen and nitrogen do not condense at the working temperature of the condenser, and will concentrate at the bottom of the condenser. If such gases fill up the condenser, the desublimation rate will decrease and the water vapor tends to be converted to snow-like ice. Such ice has lower heat conductivity compared to solid and smooth ice (Figure 2) and could result in slower desublimation or condensation of the water vapor.

Figure 2: Coils that are covered with solid and smooth ice.

In summary, the design of the ice condenser affects both product quality and the overall health of the freeze-drying system. An efficient designed ice condenser is essential for a successful freeze-drying cycle and achieving the best product quality.

Reference

1. Pikal MJ. 2006. Freeze Drying. In Swarbrick J, editor Encyclopedia of Pharmaceutical Technology, 3 ed., New York: Informa Healthcare USA Inc. p 1807 - 1833.

2. Pikal MJ, Roy ML, Shah S 1984. Mass and heat transfer in vial freeze-drying of pharmaceuticals: Role of the vial. Journal of Pharmaceutical Sciences 73(9):1224-1237.

3. Rambhatla S, Tchessalov S, Pikal M 2006. Heat and mass transfer scale-up issues during freeze-drying, III: Control and characterization of dryer differences via operational qualification tests. AAPS PharmSciTech 7(2):E61-E70.

4. Haseley P, Oetjen G-W. 2004. Intsallation and Equipment Technique. In Halseley P, Oetjen G-W, editors. Freeze-Drying, 2 ed., Weinheim: WILEY-VCH Verlag GmbH.

![]()